INLINE IMAGING INFRARED I3LASWELD

I3LASWELD

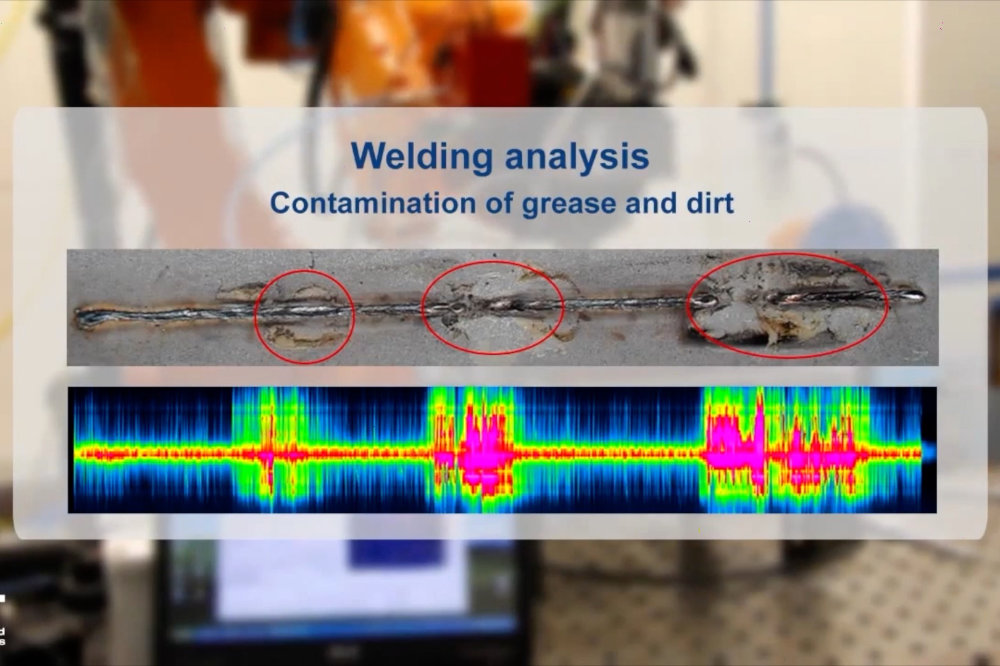

On line Infrared Imaging system for assessing in real time the quality of laser welding processes

Defects

Main characteristics

I3LASWELD – News

New Infrared Technologies (NIT), in collaboration with the AIMEN Centro Tecnológico, has developed the I3LASWELD system for the inline quality control of laser welding processes, capable of detecting defects in weld seams in real time and identifying defective parts.

The I3LASWELD system (Inline Infrared Imaging Laser Welding QA) is based on a high speed infrared camera (1 kHz) manufactured by NIT, opto-mechanically coupled to the laser optics, which continuously monitors the geometry of the melt-pool.

I3LASWELD – Promo video

| TECHNICAL SPECIFICATIONS |

| OPTICAL SENSOR | Uncooled infrared high-speed TACHYON 16k CAMERA |

| INFRARED BAND OF DETECTION | MWIR (1 – 5 microns) |

| IMAGE RESOLUTION | 64 x 64 (pixel size: 50 um x 50 um) |

| FRAME RATE | 1000 images per second |

| COMMUNICATION | Gigabit Ethernet |

| POWER | Power-Over-Ethernet (8 W) |

| ENCLOSURE | Ruggedized IP67-rated |

| OPTICAL INTERFACE | CS-mount |

| SENSOR DIMENSIONS (MM) | 66 x 62 x 62 (no optics) |

| PROCESSING UNIT | Industrial PC, Intel Dual Core i5 @ 2 GHz, 4 GB RAM |

| DEFECTS | Holes, pores, lack of penetration, lack of fusion, flase friends, underfilling |